guide

Our operational excellence guide

Every eBook, template, and guide to the world of continuous improvement, Lean, Six Sigma, Kaizen, and project management

Everything you need to know about operational excellence

Operational excellence is an organized approach to finding opportunities that can help a business meet its goals of increasing profits, reducing costs, and driving innovation.

The discipline has existed for over 80 years and takes many guises, covering an array of tools and techniques all designed to improve customer experience (delivering the greatest value).

For a few highly successful organizations, such as Toyota, GE, Ford, Motorola, and Nike, the world of improvement has underpinned their success. But it isn’t exclusive to these powerhouses.

Spanning well-known tools, techniques, and theories, including Lean, Six Sigma, PDCA, Kaizen, and beyond, operational excellence is the passion of improvement and project professionals concerned with increasing efficiency and eliminating wastage in their processes.

But what does operational excellence mean? What is its relationship with continuous improvement, process analysis, Lean, Six Sigma, and other techniques? What are the common challenges with the discipline and how can you overcome them?

This is your guide to operational excellence and how it can help your organization deliver repeatable strategic value to drive growth in your organization.

What is operational excellence?

At its simplest, operational excellence is a philosophy. It is the mindset that problem solving, and leadership can drive continuous improvements in your business.

It empowers entire businesses to be involved in improving a customer’s experience and can also be referred to as process excellence and business excellence.

However, there are many layers to operational excellence which can make it hard to define, and perhaps harder to truly embrace. Part of that is that operational excellence and continuous improvement are often confused.

Continuous improvement is an on-going attempt to improve your products, services, and processes. Unlike business transformation, continuous improvement happens incrementally, often in a project management setting, with countless improvements adding up to provide considerable value.

Operational excellence takes these continuous improvements and couples it with concepts like standard work, project management, and a philosophical shift to support sustainable improvement across your entire business.

Operational excellence is about culture. It is creating an environment where your team are valued and empowered. With operational excellence you can see how value flows through your organization, and your team are given the tools to make the changes they need to delight your customers.

Operational excellence is therefore is the foundation, but it takes concepts such as continuous improvement, project management, process analysis, PDCA, Kaizen, Lean, and Six Sigma to reach a state of business excellence.

With the right culture, systems and mentality, improvement becomes part of everyday work, and can provide incremental value to businesses seeking a new route of competitiveness and achieving operational excellence.

Operational excellence cheat sheet

- 3Cs: Three questions to correct a problem – concern, cause and countermeasure.

- 7 wastes: The 7 types of waste in a process – transport, inventory, motion, waiting, over-processing, over-production, and defects.

- Affinity diagram: A means to organize data and ideas relating to your process.

- Cause and effect diagram: A problem-solving tool used to form relationships between effects and causes. The effect is revealed via branches (fishbones) showing different causes of it.

- Control charts (Shewhart charts): A chart that shows if a process is in control.

- COPQ: What is the cost of failing to meet a customer’s expectation, covering views such as internal, external, inspection, prevention and missed opportunities.

- Countermeasure: The actions taken to address the root causes of problems which prevent you from achieving your goals.

- Continuous improvement: Increasing business effectiveness by reducing inefficiencies, frustrations, and waste (time, effort, material, etc.).

- Daily management: Giving daily attention to issues which occur within business as usual.

- DMAIC: A main concept of Six Sigma methodology, a process covering define, measure, analyze, improve and control.

- Flow: The state of a process in which the parts move from one step to the other in a steady, continuous stream without reducing quality.

- Lean: The striving of avoiding waste, boosting quality and driving continuous improvement in all processes.

- Operational excellence: The destination of continuous improvement activity is reaching a state of operational excellence, where all employees can see the flow of value to the customer, and fix that flow before it breaks down.

- PDCA: Plan-Do-Check-Act is a four-step business management method to continuously improve processes and products.

- Root cause: The core reason for an issue with a process.

- SIPOC: A tool to summarize inputs and outputs of processes. It covers suppliers, inputs, process, outputs, and customers.

- Six Sigma: Management techniques to improve processes by reducing likelihood of errors / defects. It’s directly connected to the DMAIC system.

- Value stream mapping: A process map that captures information, process flow and performance data and looks at current vs future states of a process.

- Voice of the Customer: The “Voice of the Customer” is the term used to describe the stated and unstated needs or requirements of the customer.

- Yokoten: The Japanese phrase for horizontally deploying learnings / method is all about identifying issues, using a process, sharing results and then applying this elsewhere to create a larger impact on the business.

The pillars of operational excellence

Let’s take a closer look at the four pillars of operational excellence, the term’s origins, the standard frameworks used, and the simple steps you can take to achieve excellence.

We’ll begin with the four pillars of operational excellence.

1.

A commitment to process

2.

Enabling cross-organization collaboration

3.

Embedding a culture of measurement, learning and communication

4.

Adopting technology to find efficiencies within the improvement process

Excellence origins

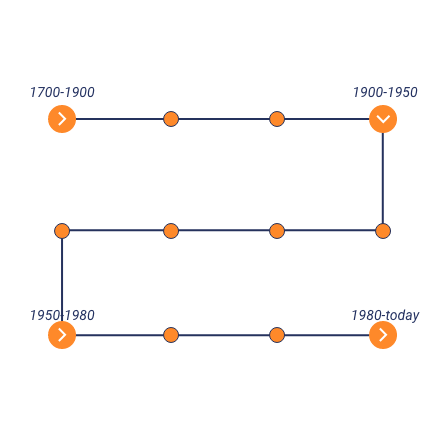

From Gosset’s statistical test to Motorola’s Six Sigma success, the seeds of operational excellence were planted in the 1700s.

The history of operational excellence splits in two – Lean and Six Sigma.

Lean is synonymous with Toyota in the first half of the 1900s, and its eventual transplant to Western management thanks to the seminal book, ‘The Machine that Changed the World’ and the NBC special covering the work of Deming in Japan and his PDCA model.

Six Sigma began with Guinness brewery and shot into the conscience of business leaders with Motorola in the 1980s, with their success inspiring the likes of GE to seek operational excellence.

Operational excellence frameworks

Whilst navigating the world of operational excellence, it is helpful to categorize the different theories / approaches within the space, what we call ‘frameworks’.

Lean Management

Lean focuses on shared responsibility and leadership for identifying and eliminating waste across your business. It has 5 steps:

- Identifying value: What do you deliver to customers and what doesn’t give them value?

- Mapping value stream: Map out the people, actions, outputs and systems involved in a process.

- Creating flow: Apply techniques to address problems, bottlenecks etc. and remove them.

- Establishing pull: Shift your business to optimize resources and process based on demand.

- Continuously improving: Monitor and control the performance of your new process.

Kaizen

Kaizen comes from two Japanese words: ‘kai’ meaning ‘change’ and ‘zen’ meaning ‘good’. To summarize the Kaizen approach:

- Toyota: The approach originated in the 1980s from Toyota, the originators of Lean.

- Empower: Employees are encouraged to suggest ideas and solutions for process flow.

- Grassroots: It is a bottom-up approach where small improvements create big change.

- Silo busting: Kaizen promotes cross-team working and alignment to one goal – improvement.

- Events: A flagship element of the approach, here teams hone in on projects to address particular issues.

Six Sigma

Six Sigma (6σ) is a statistical approach to minimizing defects in a process. 4 things you need to know about Six Sigma:

- 6 principles: Customer focus, understand the how, make processes flow, reduce waste, stop defect variation, collaborate and create data-informed systems.

- DMAIC: This is the go-to method for problem-solving.

- Toolset: Many tools are used here, but control charts, FMEA and process mapping are prominent – disagreement exists over what tools are involved, however.

- DPMO: The measurement of improvement – Six Sigma means 3.4 defects per million opportunities.

Operational excellence tools

As your business seeks operational excellence there are tools that can be applied throughout the process. These are some popular options.

Kanban

The Kanban board is a way to visualize blockers in your workflow and is a useful way to easily spot where improvements might be needed.

A3

A3 refers to A3 paper reports which address lessons post PDCA, covering current state problems, solutions and a plan to address these issues.

PDCA

Plan: Define your goals

Do: Implement plan

Check: Assess results

Act: Adjust plan

Just do it

A log of actions, context, results and expected benefit. Involving action plans and concern & countermeasure sheets.

Value Stream Mapping

A process map that captures information, process flow and performance data, involving current state (what is the issue right now) and future state (ideal scenario) map.

Root Cause Analysis

Covering tools such as FMEA, 5 Whys and Fishbone, root cause analysis seeks the core reasons your process is stuttering and offers tools to identify the cause.

Kaizen Events

A short structured problem-solving event, typically over a week, where 100% of the time is spent identifying how to improve a process.

Gemba Walks

An observation of the process in situ, meaning managers watch the actual production process and use it as a human way to capture data and ideas on how to achieve greater improvement.

Benchmarking

A means of setting existing performance metrics and then comparing future performance to these. Benchmarks can be internal or external.

Applying continuous improvement

Two core applications of continuous improvement exist – daily management and improvement projects.

Daily management

Several top-level continuous improvement cycles exist, but none are more prevalent than Deming’s Plan, Do, Check, Act model.

This can be used in what is referred to as daily management, daily kaizen or just ‘good ops’.

Upfront effort will be spent working with teams to establish a base level of operational discipline to provide a foundation to understand what the plan should be.

By applying techniques such as the below you can establish a baseline of quality which can then be continually monitored and improved:

- Demand profiling

- Capacity planning

- Root cause analysis

- Performance dashboards

- Observation scheduling

- Visual management

- Skills and training matrices

- Leader standard work

These tools are used in order for you to:

- Understand how the work should be done

- Gauge the level of performance expected

- Do the defined work

- Check and review performance

- Review and act on any improvement needed

Improvement as a project

Once you have a baseline of performance, you can turn to improvement methods and tools for projects which drive sustainable change.

How you manage improvement is important as it will help ensure you are delivering the right improvement in the right way to give you sustainable results.

There are several approaches to delivering improvement:

Just do it: as covered above, here it’s about logging what you’ve done, the results and improving.

Countermeasures: Implement a quick fix and investigate the root cause. Apply another fix and then analyze.

Root cause problem solving: Define your problem by using tools such as value stream maps, 5 why’s and FMEA, fix and then form an action plan to address the root cause, measure the impact and repeat.

DMAIC: Define, measure, act, improve and control the process improvement, involving SIPIOC, stakeholder analyses, pareto chart, process mapping etc.

Project management: An organized approach to take your activity from definition through to completion.

Diagnostic: Define your problem and apply a Six Sigma toolset, including process capability and measurement system analysis.

Intervention: Apply Lean tools such as 5s, Kanban, Takt, mistake proofing and theory and constraints.

Kaizen event: A week-long analysis of a problem and concentrated effort to make a clear improvement.

Building an excellence culture

When seeking operational excellence through continuous improvement, you cannot escape the importance of building the right culture.

Try these suggestions for ensuring your culture is one of collaboration, openness, and learning:

Preach

- Communicate the value of improvement projects

- Give examples of where it has worked

- Support and take part in projects

Enable

- Create virtual suggestion boxes

- Use visual management techniques

- Carve out time for improvement projects

Reward

- Document projects and replicate

- Communicate success

- Incentivize participation with reward schemes and career progression

Building an excellence team

Your improvement team exists to manage your journey to operational excellence and focus on implementing improvements in your business.

Excellence is far-reaching, meaning many people form your landscape:

Improvement Champion

Coaches improvement and supports cultural change, among other duties

Improvement Process Owner

The individual who owns the process post-project

Individual

Receives education and openly participates in improvement culture

Improvement Leadership Team

Establishes the improvement culture and shepherds resources

Company Leader

Accountable for achieving improvement goals

Project Leader

Lead project teams, create project plans and share learnings

Project Team

Plan project, execute, measure and install new processes

Project Sponsor(s)

Individuals, Supervisors, and Process Leaders who support project

Stakeholders

Agencies, Organizations, Teams, Individuals, and Customers impacted by project

Subject Matter Expert

Consulted for knowledge on a topic

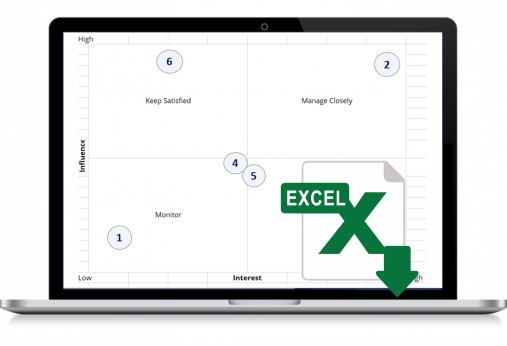

Engaging stakeholders

As an operational leader, you are overseeing a complex portfolio of change.

That change ranges overall transformation of operations, to empowering individuals to participate in real improvement, all the way to overhauling processes.

To that end, there is a landscape of stakeholders who will influence your efforts.

To successfully navigate these, you must analyze these influencers, and that begins with a stakeholder mapping exercise using an Excel template.

Operational excellence challenges

Overcoming these barriers is crucial for achieving operational excellence

- Reason and purpose

The reason you are there and the shadow it can cast – you may be seen as being in the business to cut heads. - Leadership mentality

Are your leaders there to embrace change and support you, or will they act as resistors? - Existing knowledge and capability of people

Not every member of your improvement team will have the same capabilities or knowledge. Empower and nurture when appropriate. - The base operational standards as a stable foundation (including data availability and quality)

How available is data in your business, is it treated as gold dust, or is there a reluctance to listen to data and instead focus on narrative? - Fit for purpose method

Do not over-engineer, nor cut corners, and certainly do not apply an improvement framework ill-suited to the business. - Business as usual

Be it securing the right people for your improvement team, or simply winning the hearts and minds of staff who are in constant firefighting mode, the day to day can

take the spotlight over your improvement initiatives if not addressed effectively. - The risk and opportunity of technology solutions

We’re living in a COVID-19 world and that means there is plenty opportunity to embrace virtual continuous improvement, ensure your platforms links your improvement to your business’ strategy and demonstrates ROI.

The ROI of operational excellence

The value of excellence is about more than financial gain…

There are two sources of value when it comes to operational excellence:

- The what – the outcomes or benefits that can be delivered

- The how – how it feels for the organization to deliver the above outcomes in an improvement driven way

Let’s take a look at 4 stats to prove the need for improvement, and 4 more that show you the benefits of continuous improvement.

Four stats you need to know

31%

of organizations fail to realize the benefits of their projects

Wellingtone

35%

of CEOs are confident revenue will grow within 12 months

PwC

37%

of projects fail from a lack of defined objectives

PMI

40%

of professionals struggle to link operations to strategy

PEX

The benefits of operational excellence

1. Increase employee engagement

Companies with a high level of employee engagement are more profitable by a factor of 21% (Smarp, 2020)

2. Reduce staff turn over

On average, the cost of staff turnover is $30,000 (Sodexo Engage, 2020)

3. Excellence as a standard

Pouring your team’s voices into your product / service means you’re striving toward excellence on a daily basis.

4. New day = new opportunity

Learning is the bedrock of improvement, siloes disappear, and you constantly seek growth opportunities, all for your customers’ benefit.

Operational excellence templates, eBooks, blogs, webinars, and more

Learn more about operational excellence with our dedicated resource hub.

From jargon busters and case studies to webinars, this is the home of operational excellence knowledge.

Ebook

Lead improvement in your business

Download this eBook to discover how continuous improvement can be used by your business to drive competitive advantage and delight your customers.

Guide

A guide to leading improvement

Jargon buster

The ultimate guide to excellence jargon

Trends

See where operational excellence is heading

Resources

The resources you need for process improvement

Your project management software

Our advice for getting real value from software

Comparison

DMAIC v Lean v Six Sigma

Explainer

The answer to ‘What is continuous improvement?’

Explainer

The 8 principles of continuous improvement

Explainer

What is a Kaizen Event & how can you prepare?

Explainer

10 process improvement tools you need to know

Explainer

Lean Management explained

Explainer

Six Sigma explained

Template

Download a root cause analysis template pack

Template

Download an FMEA Excel template

Template

Download a Fishbone template

Template

Download a SIPOC Excel template

Template

Download a Pareto Chart Excel template

Template

Download a stakeholder engagement template

Advice

Why you must build culture for excellence to thrive

Advice

Value stream mapping explained

Advice

8 improvement capability questions to ask

Advice

DMAIC v Six Sigma v Lean: Choosing your improvement framework

Advice

How end to end should a value stream mapping exercise be?

Explainer

4 essential analyses for creating your Value Stream Map

Advice

4 tips to facilitate your Kaizen Events

Advice

A guide to Current v Future State Maps

Advice

9 challenges every improvement leader faces

Explainer

How to explain the value of operational excellence

Resources

5 root cause analysis tools

Advice

10 benefits that come with operational excellence

Template pack

A guide to Current v Future State Maps

Improvement webinars

Gaze into the future of continuous improvement

Improvement webinars

Did COVID-19 change operational excellence?

Improvement webinars

Kaizen Institute’s look at the future of continuous improvement

Maturity model

Assess your operations’ maturity with this model

Software

Learn how i-nexus powers operational excellence

Operational excellence software

Learn all about operational excellence software and how i-nexus helps organizations like yours

Unlock scalable value from improvement projects, processes, and people – all aligned to your goals

Accelerate project delivery, instill best practices, and ensure everyone supports your goals with operational excellence software from i-nexus.

The software in this space covers several purposes and functionality.

Why you need operational excellence software

- One location for excellence

- Aligning strategic goals to operations

- Governing processes

- Reducing risks

- Tracking performance

- Responding to results

- Unearthing value

- Bringing ideas to life

- Growing your skills

Tools you’ll need from operational excellence software

- X-matrix

- Process governance

- Stakeholder management

- Portfolio and project management

- Workflow management

- Idea management

- Template and methodology management

- Learning and development management

- Root cause analysis

- Operational scorecards

- Automated reporting and KPI tracking

- Impact and benefits analysis

The benefits of using operational excellence software

1. Standardized improvement

Project replication and standardized reporting at all levels of method application, making it easier for your teams to deliver improvement as you wish.

2. Increased strategic value

Increased strategic value of improvement activities through a clear alignment of investment with business priorities.

3. Reduced project cycle times

Reduced project cycle times and subsequent increased project success rates through standard detailed plans and the ability to track progress of delivery.

4. Greater productivity

Greater productivity through the elimination of non value-adding effort via the automation of reporting and governance preparation and distribution.

Introducing i-nexus operational excellence software

Discover how operational excellence powered by i-nexus strategy software allows you to unlock repeatable value from operational activity.

Built for PMOs and Lean, Six Sigma and process professionals pursuing an excellence mindset, inside i-nexus you’ll execute your goals across portfolios, programs, and projects, exactly how you want.

i-nexus demo on-demand

Watch our on-demand demo to learn how i-nexus strategy software helps you to deliver strategic value from operational work.

i-nexus operational excellence software datasheet

Learn how to unlock repeatable value from operational activity with our operational excellence solution factsheet.